What and Why 5R Rifling?

Posted by Faxon Firearms Staff on Mar 21st 2016

Why 5R Rifling?

Recently, Faxon introduced its first 5R rifled barrels. Since then, we’ve been slammed by questions by customers wanting to understand two key questions:

- 1.What is 5R rifling?

- 2.Why is it a good choice?

It’s our pleasure to answer.

Before we delve into the specifics of what is 5R, we’ll cover the basics of rifling. Rifling consists of lands (the plateaus that interface with bullets) and grooves (the cuts into a bore) which are manufactured to help stabilize a bullet by imparting gyroscopic twist onto it in the barrel of a firearm.

As a bullet passes through a barrel the lands of a barrel directly cut/squeeze into the projective forcing it to follow the path of the rifling. This is why bullets have unique grooving on them if they are recovered intact.

“Conventional” rifling uses either 6 or 4 symmetrical lands and grooves on the bullet. Each of the lands (the raised portion of the rifling) are directly opposite one another. Likewise the grooves are opposite of one another. The vast majority of barrels Faxon and other companies use is conventionally rifled. In fact, the military and most machine guns use conventional rifling.

Why? Conventional rifling is an excellent choice that has been perfected over the years.

What is 5R Rifling?

5R is an improvement over conventional rifling by changing the shape and configuration of the lands and grooves. Conventional rifling, while effective, can be improved upon in two ways.

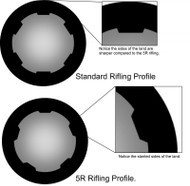

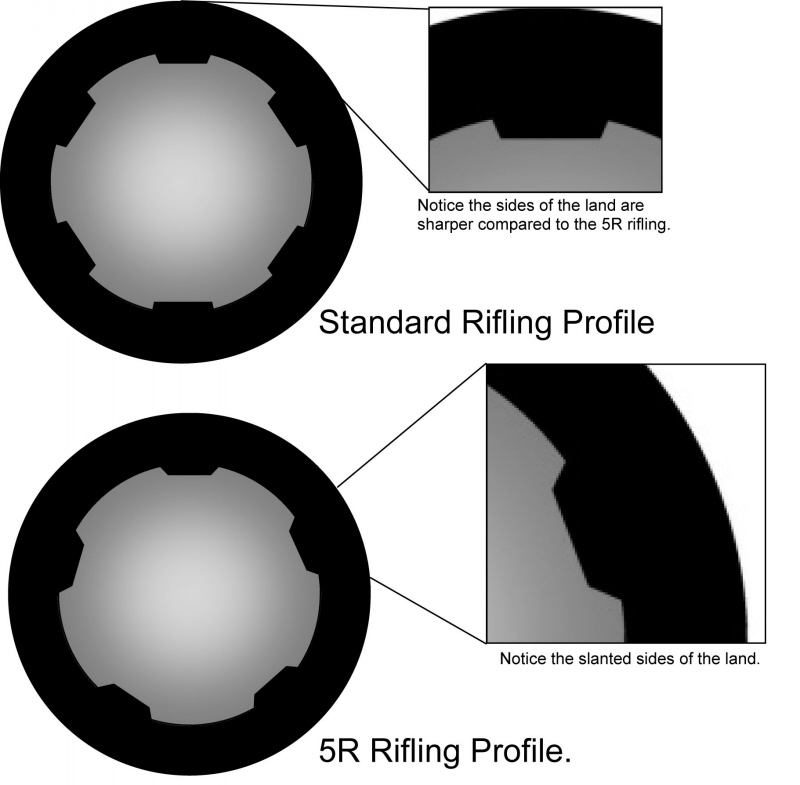

- 1. Conventional rifling has sharp 90-degree corners from the top of the land to the bottom of the groove.

- 2.Conventional rifling has lands and grooves opposing one another.

5R rifling improves upon this by using 5 lands and grooves over the even numbers which puts lands opposite of grooves. Further, the transition from the top of the land to the groove is sloped.

*Photo courtesy of the Guns & Ammo forum via Photobucket user "lovinmycaitlynn".

How does this help?

5R reduces projectile deformation as it passes through the bore during the firing sequence. By placing the lands opposite of the grooves, the bullets are no longer squeezed on opposite sides ensuring the projectile stays uniform instead of squeezing material into the grooves. More uniform projectile means better accuracy.

Secondly, by sloping the transition to the groove, the barrels become much easier to clean. In a conventionally rifled platform, these corners become depositories for lead and superheated materials left after shooting. Cleaning supplies have a hard time reaching these corners as they are incredibly small. By sloping it, cleaning supplies are easily able to get to the deposits.

Does this mean conventional rifling is no good?

Absolutely not! Conventional rifling has been slinging projectiles accurately for over 200 years and will continue to be a mainstay of Faxon’s capabilities. 5R is being offered as an upgrade for those looking for additional performance.